Product Description

FAQ:

Q1:Are you a trading company or factory?

A: Xihu (West Lake) Dis. Xihu (West Lake) Dis. Industrial Co., Ltd. has factories located in ZheJiang China, We supply high quality equipment with factory price, and owns export and import rights.

Q2:What product do you manufacture?

A:Xihu (West Lake) Dis. Xihu (West Lake) Dis. Industrial Co., Ltd. is a professional manufacturer of food machinery, glass machinery, mesh belt, mesh chain, chain, chain plate, conveyor and other mechanical equipment.

Q3:What is the payment term?

A:We accept T/T, W/U, L/C, DP and so on.

Q4: What is the delivery time?

A: It takes about 5~15 days usually after receipt of your deposit. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | 1000 |

|---|---|

| Material: | Metal |

| Inside Material: | Plastic |

| Feature: | Oil-Resistant, Acid And Alkali Resistant, Tear-Resistant, Heat-Resistant, Cold-Resistant, Wear-Resistant |

| Tensile Strength: | Strong |

| Backflex Radius: | 25mm |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What innovations and advancements have been made in modular belt technology in recent years?

In recent years, modular belt technology has seen several innovations and advancements aimed at improving performance, efficiency, and versatility. Here are some notable developments in modular belt technology:

- Advanced Materials:

New and improved materials have been developed for modular belts, enhancing their durability, strength, and resistance to wear and tear. These materials include high-performance polymers, such as polyethylene and polypropylene blends with enhanced properties. These advanced materials offer improved resistance to chemicals, impact, and abrasion, allowing modular belts to withstand harsh operating conditions and extend their service life.

- Enhanced Design Features:

Modular belts now incorporate enhanced design features that optimize their performance and functionality. These features include specialized surface patterns or textures that improve product grip and reduce slippage, enhancing the efficiency of incline or decline applications. Enhanced module shapes, such as ribbed or cleated modules, provide better product stability and control during conveying. Additionally, advancements in sprocket engagement systems and module-to-module connections have improved belt tracking, reducing the risk of misalignment and improving overall conveyor system reliability.

- Customization and Adaptability:

Recent advancements in modular belt technology have expanded customization and adaptability options. Modular belts can now be easily tailored to specific application requirements, allowing for greater flexibility in design and layout. Customization options include belt width, length, module configurations, and surface features. This adaptability enables modular belts to be seamlessly integrated into existing conveyor systems or designed for unique applications, optimizing material handling efficiency and improving overall operational performance.

- Improved Cleanability:

Hygiene and cleanability have been a focus of innovation in modular belt technology. Manufacturers have developed modular belts with smoother surfaces and reduced crevices or recesses where contaminants can accumulate. This design improvement simplifies cleaning processes, reduces the risk of bacterial growth, and enhances food safety compliance in food processing applications. Additionally, advancements in modular belt materials have resulted in increased resistance to staining, allowing for easier removal of stubborn residues and reducing maintenance efforts.

- Integration with Industry 4.0:

Modular belt technology has been integrated with Industry 4.0 concepts and smart manufacturing principles. Sensor technologies can now be incorporated into modular belts to monitor various parameters such as belt tension, speed, temperature, or product presence. This real-time data collection enables predictive maintenance, optimizing belt performance, and reducing unplanned downtime. Integration with automation systems and data analytics further enhances operational efficiency and enables intelligent material handling and process control.

- Environmental Sustainability:

There has been a growing emphasis on environmental sustainability in modular belt technology. Manufacturers are developing modular belts made from recycled or recyclable materials, reducing their carbon footprint and promoting circular economy practices. Additionally, advancements in manufacturing processes have led to reduced energy consumption and waste generation during production. These eco-friendly initiatives contribute to the overall sustainability of modular belt systems while meeting the increasing demand for environmentally responsible solutions.

In summary, recent years have witnessed significant innovations and advancements in modular belt technology. These include the development of advanced materials, enhanced design features, increased customization and adaptability, improved cleanability, integration with Industry 4.0 technologies, and a focus on environmental sustainability. These advancements have resulted in modular belts that offer improved performance, durability, hygiene, and operational efficiency, meeting the evolving needs of various industries and applications.

Can you provide examples of products or machinery that use modular belts for conveying materials?

Modular belts are widely used in various industries and applications for conveying materials. They are employed in a range of products and machinery to ensure efficient and reliable material handling. Here are some examples of products and machinery that utilize modular belts:

- Food Processing Equipment:

In the food processing industry, modular belts are extensively used in equipment such as conveyors, sorting systems, and packaging machines. They are employed to transport a wide range of food products, including baked goods, fruits and vegetables, meat and poultry, dairy products, and packaged snacks. Modular belts help ensure hygienic and gentle handling of food items, as well as facilitate efficient product flow during processing, sorting, and packaging operations.

- Beverage Bottling Lines:

In beverage bottling plants, modular belts are commonly integrated into conveyor systems for the transportation of bottles, cans, and other containers. They are utilized in various stages of the bottling process, including filling, capping, labeling, and packaging. Modular belts provide a smooth and reliable conveying surface, allowing for seamless movement of containers and ensuring precise alignment during filling and capping operations.

- Automotive Manufacturing:

In automotive manufacturing facilities, modular belts are utilized in assembly lines and material handling systems. They are employed to convey various automotive components, such as engines, transmissions, chassis parts, and interior components. Modular belts offer flexibility in configuring conveyor systems to accommodate different assembly processes and part sizes. They help streamline production and facilitate the efficient transfer of components between workstations.

- Pharmaceutical Production:

In the pharmaceutical industry, modular belts play a crucial role in conveying materials during the production of medications and medical devices. They are used in processes such as tablet and capsule handling, packaging, and labeling. Modular belts provide a clean and hygienic conveying surface, ensuring compliance with strict regulatory requirements. They enable precise positioning of pharmaceutical products during packaging and facilitate efficient material flow in pharmaceutical production lines.

- E-commerce and Logistics:

In e-commerce warehouses, distribution centers, and logistics facilities, modular belts are employed in conveyor systems for the sorting, merging, and transportation of packages and parcels. They are used to handle a wide variety of products, including boxes, cartons, totes, and polybags. Modular belts offer a reliable and flexible conveying solution in high-throughput environments, enabling efficient order fulfillment and smooth material flow in the logistics and supply chain industry.

- Packaging Machinery:

Modular belts are extensively integrated into packaging machinery, such as form-fill-seal machines, carton erectors, case packers, and palletizers. They are used to transport packaging materials, primary and secondary packaging, and finished products. Modular belts help ensure precise and synchronized movement of packages during the packaging process, optimizing productivity and minimizing product damage.

- Agricultural Equipment:

In the agricultural sector, modular belts are utilized in equipment such as harvesters, seed processing machines, and sorting systems. They are employed to handle crops, seeds, and other agricultural products during harvesting, processing, and packaging operations. Modular belts provide reliable conveying surfaces that can withstand outdoor conditions and facilitate the efficient movement of agricultural materials.

- Material Handling in Warehouses:

Modular belts are used in warehouse material handling systems, including conveyor systems for order picking, sorting, and distribution. They are employed to transport a wide range of products, including packages, cartons, and bins. Modular belts offer customization options to meet specific warehouse requirements, such as the ability to handle different product sizes and weights, adapt to varying layouts, and provide reliable and efficient material flow.

These are just a few examples of the many products and machinery that utilize modular belts for conveying materials. The versatility, reliability, and customization options of modular belts make them a popular choice in various industries where efficient and precise material handling is essential.

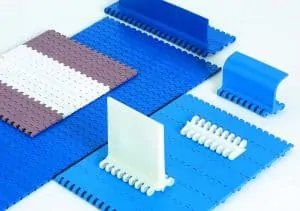

Can you describe the various types and configurations of modular belts available in the market?

Modular belts are available in a wide range of types and configurations to suit different material handling needs and industry requirements. These belts are designed with various features, such as different module shapes, surface patterns, and materials. Here is an overview of the main types and configurations of modular belts available in the market:

- Flat Top Belts:

Flat top belts consist of flat, rectangular modules that interlock to form a continuous conveying surface. They provide a smooth and even transport platform for a wide range of products. Flat top belts are commonly used in industries such as food processing, packaging, and general manufacturing. They are suitable for handling items that require stable support, such as cartons, boxes, and containers.

- Flush Grid Belts:

Flush grid belts feature modules with a grid-like pattern of openings. The grid pattern allows for better airflow, drainage, and easy cleaning. These belts are often used in applications where liquids or debris need to be drained or removed from the conveying surface. Flush grid belts are commonly employed in industries such as food and beverage processing, where hygiene and cleanliness are critical.

- Raised Rib Belts:

Raised rib belts have modules with raised ribs or bars running along the length of the belt. The raised ribs provide additional grip, ensuring positive engagement with the conveyed products. These belts are suitable for inclined or declined conveying applications or when items need extra stability during transport. Raised rib belts are commonly used in industries such as incline/decline transportation, bakery, and meat processing.

- Mold to Width Belts:

Mold to width belts are designed to be easily and precisely customized to fit specific conveyor widths. They consist of modules that can be individually removed or added to achieve the desired belt width. Mold to width belts offer flexibility in configuring conveyor systems and can be adapted to changing production needs. These belts are commonly used in industries that require frequent belt width adjustments or when retrofitting existing conveyor systems.

- Open Grid Belts:

Open grid belts feature a grid-like pattern of open areas between the modules. The open design allows for good airflow and drainage, making these belts suitable for applications where cooling, drying, or drainage is required. Open grid belts are commonly used in industries such as food processing, cooling processes, and drying applications.

- Perforated Belts:

Perforated belts have modules with perforations or holes throughout the surface. The perforations allow for better drainage, airflow, and visibility. These belts are often used in applications where liquids or small particles need to be drained or filtered. Perforated belts are commonly employed in industries such as food processing, sorting, and wastewater treatment.

- Flighted Belts:

Flighted belts have modules with integrated flights or cleats along the conveying surface. The flights help to contain and elevate products during transport, preventing them from sliding or falling off the belt. Flighted belts are used in applications where inclined or vertical conveying is required, such as in bulk handling or incline/decline transportation. They are commonly employed in industries such as agriculture, mining, and bulk material handling.

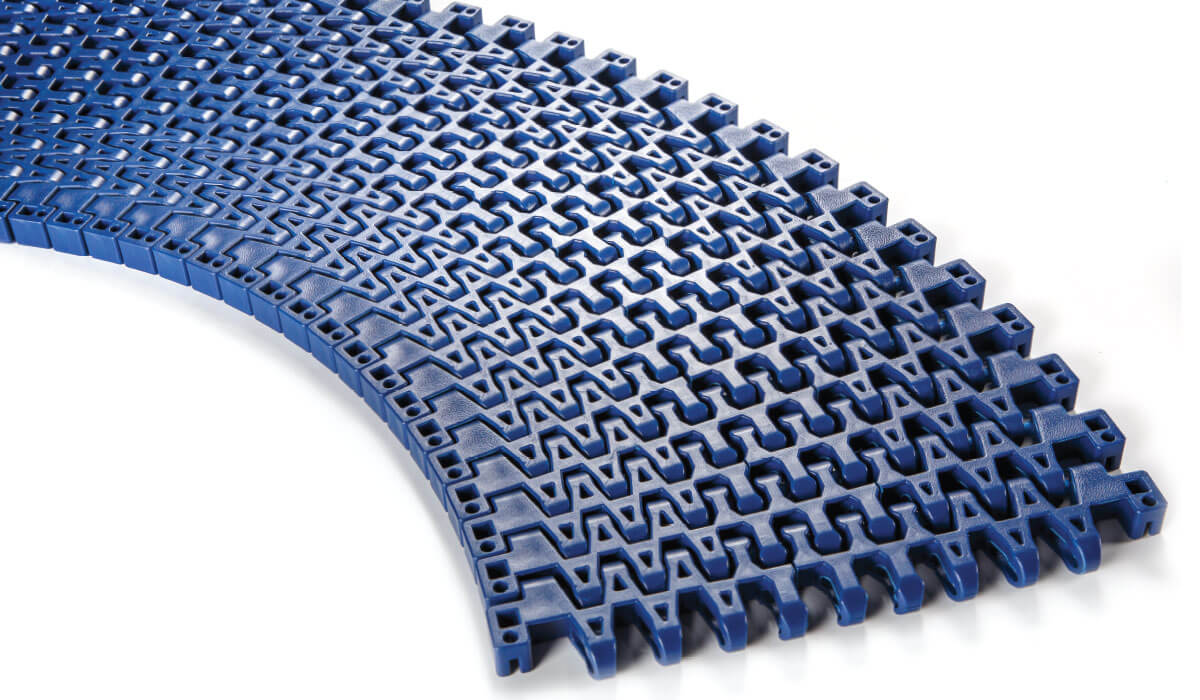

- Radius Belts:

Radius belts are designed to navigate tight curves or bends in conveyor systems. They feature modules with a curved shape that allows the belt to smoothly transition around corners. Radius belts are commonly used in industries where space is limited or when conveyor systems need to follow complex layouts. They are often found in industries such as packaging, bottling, and material handling in confined spaces.

- Wire Mesh Belts:

Wire mesh belts are composed of metal modules or links, typically made of stainless steel. These belts offer high strength, durability, and excellent heat resistance. Wire mesh belts are used in applications where heavy loads, high temperatures, or strict sanitation requirements are present. They are commonly employed in industries such as automotive manufacturing, heat-treatment processes, and industrial ovens.

These are some of the main types and configurations of modular belts available in the market. Each type offers specific features and benefits, allowing for customized solutions in various industries and material handling applications.

editor by CX 2024-04-17