Product Description

FAQ

Q1:Are you a trading company or factory?

A: Xihu (West Lake) Dis. Xihu (West Lake) Dis. Industrial Co., Ltd. has factories located in ZheJiang China, We supply high quality equipment with factory price, and owns export and import rights.

Q2:What product do you manufacture?

A:Xihu (West Lake) Dis. Xihu (West Lake) Dis. Industrial Co., Ltd. is a professional manufacturer of food machinery, glass machinery, mesh belt, mesh chain, chain, chain plate, conveyor and other mechanical equipment.

Q3:What is the payment term?

A:We accept T/T, W/U, L/C, DP and so on.

Q5: What is the delivery time?

A: It takes about 5~15 days usually after receipt of your deposit. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

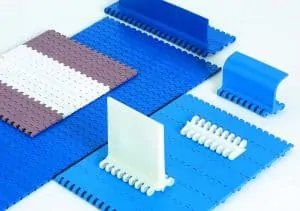

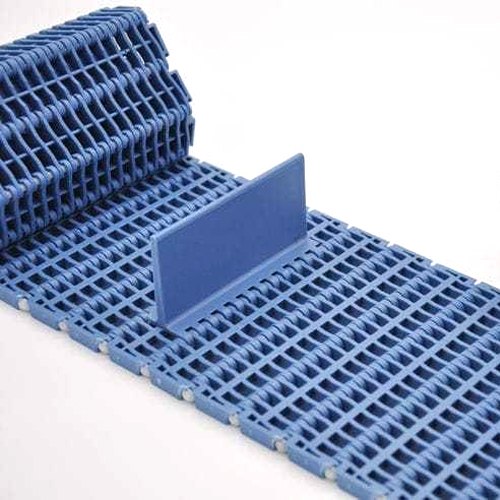

| Type: | 1000 |

|---|---|

| Material: | Metal |

| Inside Material: | Plastic |

| Feature: | Oil-Resistant, Acid And Alkali Resistant, Tear-Resistant, Heat-Resistant, Cold-Resistant, Wear-Resistant |

| Tensile Strength: | Strong |

| Backflex Radius: | 25mm |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Are there sustainability aspects associated with the use of modular belts in material handling systems?

Yes, there are sustainability aspects associated with the use of modular belts in material handling systems. Here’s a detailed explanation:

The adoption of modular belts in material handling systems brings several sustainability benefits, addressing environmental, social, and economic aspects of sustainability.

- Resource Efficiency:

Modular belts are designed to optimize resource efficiency during their production and use. The manufacturing process of modular belts has become more environmentally friendly, with advancements in materials and production techniques. Manufacturers are increasingly utilizing recycled materials in the production of modular belts, reducing the demand for virgin resources. Additionally, modular belts often have a longer service life compared to traditional conveyor belts, reducing the frequency of replacements and the associated resource consumption.

- Energy Efficiency:

Modular belts contribute to energy efficiency in material handling systems. Their low friction characteristics and optimized design features minimize energy losses during operation. Reduced friction between the belt and conveyor components results in lower power requirements for driving the belt, leading to energy savings. The use of precise sprocket engagement and accurate belt tracking also helps to optimize power transmission and minimize energy waste. Overall, the energy efficiency of modular belts contributes to lower operational costs and reduced environmental impact.

- Waste Reduction:

Modular belts are designed for durability and longevity, resulting in reduced waste generation. Their robust construction and resistance to wear and tear extend their service life, reducing the frequency of belt replacements. Moreover, modular belts are often repairable, with the ability to replace individual modules or segments instead of replacing the entire belt. This repairability reduces waste generation and promotes a more sustainable approach to maintenance and replacement in material handling systems.

- Hygiene and Cleanability:

Hygiene is a significant aspect of sustainability in industries such as food processing and pharmaceuticals. Modular belts are designed with cleanability in mind, featuring smooth surfaces and reduced crevices where contaminants can accumulate. This design minimizes the risk of bacterial growth and improves food safety compliance. Additionally, some modular belts incorporate antimicrobial additives that further enhance hygiene and reduce the need for chemical cleaning agents. The improved cleanability of modular belts contributes to sustainable operations by ensuring product integrity, reducing waste due to contamination, and minimizing the use of cleaning chemicals.

- Adaptability and Flexibility:

Modular belts offer adaptability and flexibility in material handling systems, contributing to sustainability. Their modular design allows for easy customization and reconfiguration, enabling efficient use of space and resources. Modular belts can be easily integrated into existing conveyor systems or designed for unique applications, optimizing material flow and reducing the need for extensive system modifications or new installations. This adaptability and flexibility result in resource savings and increased operational efficiency, aligning with sustainable practices.

- Recyclability:

Many modular belts are made from recyclable materials, contributing to the circular economy. At the end of their service life, modular belts can be recycled and processed into new products, reducing waste and conserving resources. The recyclability of modular belts aligns with sustainable waste management practices and reduces the environmental impact associated with belt disposal.

In summary, the use of modular belts in material handling systems offers several sustainability aspects. These include resource efficiency, energy efficiency, waste reduction, improved hygiene and cleanability, adaptability and flexibility, and recyclability. By incorporating modular belts into their operations, companies can reduce their environmental footprint, lower energy consumption, minimize waste generation, and promote sustainable practices in material handling processes.

What factors should be considered when selecting modular belts for different industrial applications?

When selecting modular belts for different industrial applications, several factors should be taken into consideration. Choosing the right modular belt requires evaluating the specific requirements of the application and matching them with the characteristics and capabilities of the belt. Here are some key factors to consider:

- Product Characteristics:

The nature of the products being conveyed is an important factor in modular belt selection. Consider the size, weight, shape, and surface properties of the products. For example, if conveying small items or products with irregular shapes, modular belts with smaller module sizes or specialized inserts may be required to ensure proper grip and stability. For heavy or bulky products, belts with higher load-carrying capacities and robust construction may be necessary.

- Operating Environment:

The operating environment plays a significant role in modular belt selection. Consider factors such as temperature, humidity, presence of liquids or chemicals, and exposure to abrasion or impact. Some modular belts are specifically designed to withstand extreme temperatures or harsh chemical environments. For applications where frequent washdowns are required, belts with high resistance to water and cleaning agents are essential. Additionally, if the application involves abrasive materials or heavy impact, belts with reinforced or wear-resistant modules should be considered.

- Conveyor Configuration:

The layout and configuration of the conveyor system should be considered when selecting a modular belt. Evaluate factors such as the presence of curves, inclines or declines, and the need for merging or diverting products. Modular belts offer flexibility and adaptability to different conveyor configurations, but it’s important to select a belt that can smoothly navigate the desired layout without causing product damage or operational issues. Belts with the appropriate module flexibility, pitch, and turning radius should be chosen for the specific conveyor configuration.

- Required Conveyor Performance:

Define the desired performance characteristics of the conveyor system. Consider factors such as speed, acceleration, and deceleration requirements. Modular belts have different capabilities regarding maximum speed and acceleration, and selecting a belt that can meet the performance demands of the application is crucial. Additionally, if the application requires precise indexing, positioning, or accumulation, modular belts with integrated features such as indexing modules or low back-pressure accumulation systems should be considered.

- Maintenance and Cleanability:

Assess the maintenance and cleanability requirements of the modular belt. Consider factors such as ease of cleaning, resistance to contaminants, and the ability to perform routine maintenance tasks. Modular belts with smooth and non-porous surfaces are easier to clean and resistant to bacterial growth. Belts that allow for easy access and module removal simplify maintenance activities, such as cleaning under the belt or replacing damaged modules. Considering the maintenance and cleanability features of the belt can contribute to overall operational efficiency and hygiene in industries with strict sanitation requirements.

- Industry Regulations and Standards:

Ensure that the selected modular belt meets relevant industry regulations and standards. Different industries, such as food processing, pharmaceuticals, and electronics, have specific requirements for material handling equipment. Compliance with regulations related to food safety, hygiene, electrical safety, and chemical resistance may be necessary. Look for modular belts that are certified or compliant with industry-specific standards to ensure they meet the necessary requirements and ensure product quality and safety.

- Budget and Total Cost of Ownership:

Consider the budget and the total cost of ownership over the belt’s lifespan. While upfront costs are important, it’s essential to evaluate the long-term durability, reliability, and maintenance requirements of the modular belt. A belt that offers extended service life, minimal downtime, and low maintenance needs may result in lower overall costs and higher operational efficiency in the long run.

By carefully considering these factors, it becomes possible to select a modular belt that is well-suited for the specific industrial application, ensuring optimal performance, longevity, and cost-effectiveness.

In what industries are modular belts commonly employed for material handling?

Modular belts find wide application in various industries where efficient and reliable material handling is essential. The versatility, durability, and customizable nature of modular belts make them suitable for diverse handling needs. Here are some industries where modular belts are commonly employed:

- Food and Beverage:

The food and beverage industry extensively utilizes modular belts for material handling. These belts are ideal for transporting food products, including baked goods, fruits, vegetables, meat, poultry, and packaged items. Modular belts with specialized surface patterns or coatings ensure gentle handling, prevent product damage, and meet hygiene requirements. They are also resistant to chemicals and can withstand washdown procedures, making them suitable for food processing and packaging applications.

- Packaging and Logistics:

Modular belts play a crucial role in the packaging and logistics industry. They are commonly used in conveyor systems for packaging, sorting, and distribution operations. Modular belts provide reliable transportation of items, such as boxes, cartons, bags, and parcels. The ability to customize the belt’s surface and accessories allows for efficient sorting, merging, and diverting of products. Modular belts also facilitate accumulation and indexing, enabling smooth flow control in packaging lines and distribution centers.

- Automotive and Manufacturing:

In the automotive and manufacturing industries, modular belts are employed for handling various components and assemblies. They are used in assembly lines, machining operations, and material transfer processes. Modular belts can handle heavy loads and provide precise positioning, ensuring smooth and efficient movement of automotive parts, machinery components, and other manufactured goods. The durability of modular belts allows them to withstand the demanding conditions of manufacturing environments.

- Airport and Baggage Handling:

Modular belts play a critical role in airport baggage handling systems. They are used to transport luggage and other items through conveyor systems, including check-in areas, security checkpoints, and baggage claim areas. Modular belts with low-friction surfaces and gentle handling characteristics ensure the safe and efficient movement of baggage, reducing the risk of damage. The ability to accommodate inclines, declines, and curves makes modular belts suitable for complex airport layouts and varying elevation changes.

- Pharmaceutical and Healthcare:

The pharmaceutical and healthcare industries rely on modular belts for material handling in various processes. Modular belts are used in pharmaceutical manufacturing, packaging, and distribution facilities. They provide a clean and hygienic solution for transporting medications, medical devices, and healthcare products. Modular belts with antimicrobial properties or easy-to-clean surfaces support the industry’s stringent hygiene standards. These belts also facilitate the precise positioning and handling of delicate or sensitive pharmaceutical products.

- E-commerce and Retail:

In the e-commerce and retail sectors, modular belts are utilized for efficient material handling in warehouses, fulfillment centers, and distribution hubs. They enable the movement of packages, boxes, and totes along conveyor systems, ensuring timely order fulfillment and shipping. Modular belts with high load capacities and customizable configurations allow for the handling of a wide range of products, from small items to larger merchandise. The modular design of these belts also enables easy integration with automated systems, such as barcode scanners and robotic pick-and-place systems.

- General Manufacturing:

Modular belts find applications in general manufacturing industries, including electronics, consumer goods, textiles, and more. They are used for material handling in assembly lines, testing processes, and product packaging. The flexibility and adaptability of modular belts make them suitable for diverse manufacturing environments and product types. Modular belts can handle both lightweight and heavy items, making them versatile for a wide range of manufacturing applications.

These are just a few examples of the industries where modular belts are commonly employed for material handling. The modular design, durability, and customizable features of these belts make them a preferred choice for efficient and reliable transportation of goods in various industrial sectors.

editor by CX 2024-04-15