Product Description

1000 Series Plastic Modular Conveyor Belt for manufacturing

Advantages:

1 This modular conveyor belt are convenient to assembly and maintain

2. This modular conveyor belt can bear High mechanical strength

3. This modular conveyor belt has Excellent product handling performance

4. This modular conveyor belt are wear resistance and Oil Resistant

5. We are professional conveyor system manufacturer,our product line contain: modular belt, slat top chain, conveyor spare parts, conveyor system.

6. We can provide good after-sale service.

7. Every products can be customized

Application :

Specifications:

| Belt type | Pitch(mm) | Material | Belt Weight kg/m2 |

Working load | Backflex radius |

| 1000-A | 25.4 | POM | 6.5 | 22000 | 25 |

| PP | 4.25 | 11000 | |||

| PE | 4.6 | 5000 |

Product display:

Exhibitions:

Our workshop:

Package delivery:

Company Introduction:

Xihu (West Lake) Dis. Xihu (West Lake) Dis. Industrial Co., Ltd., founded in 1998, is located in HangZhou. The company covers a total area of 14000 square meters. It is a high-tech enterprise integrating scientific research and development, engineering design, production and installation, and commissioning services.It is a set of independent research and development, production, processing, sales as 1 of the automation equipment and machinery manufacturers.

If you order from us, we are sure that you will be greatly satisfied with our products and the most competitive price.We are mainly majored in Conveyor Equipments for nearly 20 years so you can be relieved for our products. We are very looking forward to receive your any enquiries or orders. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | 1000 |

|---|---|

| Material: | Metal |

| Inside Material: | Plastic |

| Feature: | Oil-Resistant, Acid And Alkali Resistant, Tear-Resistant, Heat-Resistant, Cold-Resistant, Wear-Resistant |

| Tensile Strength: | Strong |

| Backflex Radius: | 25mm |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can you provide insights into the future trends and developments in modular belt technology?

In the future, modular belt technology is expected to continue evolving and adapting to advancements in material science, automation, and industry requirements. Here are some insights into the future trends and developments in modular belt technology:

- Advanced Materials:

The development of new materials and composites is likely to play a significant role in the future of modular belt technology. Manufacturers are continually exploring materials with enhanced strength, wear resistance, and chemical resistance properties. Advanced materials, such as high-performance polymers and reinforced fibers, may be utilized to create modular belts that can withstand even more demanding operating conditions and extend their service life. Additionally, the use of sustainable and recyclable materials may become more prevalent to align with environmental goals and regulations.

- Smart and Connected Belts:

The integration of smart and connected technologies is expected to shape the future of modular belt systems. Sensors and monitoring devices can be incorporated into modular belts to provide real-time data on belt health, performance, and maintenance requirements. This data can be used to optimize operations, predict maintenance needs, and improve overall system efficiency. Smart belts can also enable better tracking and tracing of products, enhancing supply chain transparency and quality control.

- Automation and Robotics:

The increasing adoption of automation and robotics in material handling will likely influence the development of modular belt technology. Modular belts can integrate seamlessly with automated systems, allowing for efficient and precise movement of products. Future modular belt systems may be designed to accommodate robotic interfaces, enabling collaborative or fully automated material handling processes. This integration can improve productivity, reduce labor requirements, and enhance workplace safety.

- Enhanced Performance Features:

Future modular belt systems may incorporate enhanced performance features to cater to specific industry needs. This could include specialized surface coatings for improved grip or reduced friction, modular designs with customizable shapes and sizes, or innovative mechanisms for quick and tool-less belt assembly and disassembly. Manufacturers will likely continue to focus on developing features that enhance belt performance, durability, and ease of maintenance, allowing for more efficient and reliable material handling operations.

- Energy Efficiency and Sustainability:

Energy efficiency and sustainability will remain important considerations in future modular belt technology. Manufacturers may further optimize belt designs to minimize friction and energy consumption, improving overall system efficiency. Additionally, the use of eco-friendly materials and the incorporation of sustainable practices, such as recycling and waste reduction, are likely to be emphasized to align with global sustainability goals. The development of modular belts that contribute to a circular economy by being easily recyclable or biodegradable may also be explored.

Overall, future trends in modular belt technology will revolve around advanced materials, smart and connected capabilities, automation and robotics integration, enhanced performance features, and a continued focus on energy efficiency and sustainability. These developments aim to meet the evolving needs of industries, optimize material handling processes, and contribute to more efficient, sustainable, and intelligent conveyor systems.

Can modular belts be customized for specific industries or conveyor configurations?

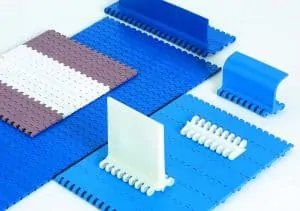

Yes, modular belts can be customized to meet the specific requirements of different industries or conveyor configurations. The modular design of these belts allows for flexibility in tailoring them to specific applications, ensuring optimal performance and functionality. Here are some ways in which modular belts can be customized:

- Material Selection:

Modular belts can be customized by selecting the appropriate materials based on the industry or application requirements. Different industries have specific material handling needs, such as food processing, pharmaceuticals, automotive, or electronics. For example, in food processing, modular belts made of FDA-approved materials that are resistant to chemicals and easy to clean are often used. In industries where high temperatures or abrasive materials are present, modular belts with heat-resistant or wear-resistant materials can be selected. By choosing the right material, the belt can be customized to withstand the demands of the specific industry.

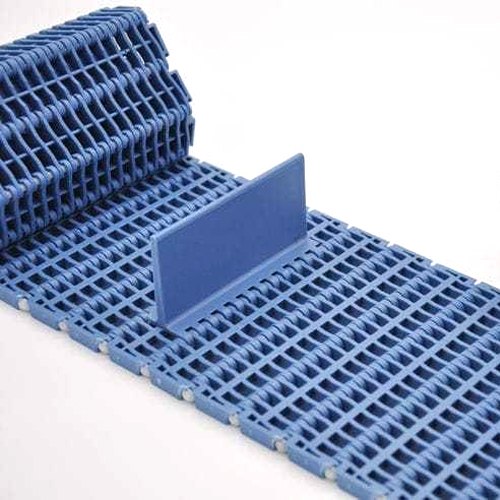

- Module Design:

The design of individual modules can be customized to enhance the performance of the modular belt. Modules come in various shapes, sizes, and surface textures to accommodate different product characteristics and conveyor requirements. For example, modules with cleats or flights can be added to provide better grip and prevent product slippage on inclined or declined conveyors. Modules with rollers or ball transfers can facilitate smoother product transfers between conveyors. By selecting or customizing the module design, the modular belt can be tailored to specific product handling needs and conveyor configurations.

- Accessories and Features:

Modular belts can be customized with accessories and features to enhance their functionality in specific industries or conveyor configurations. Accessories such as side guards, guide rails, or diverts can be added to ensure proper product orientation and containment. Additionally, specialized features like low back-pressure accumulation systems or indexing modules can be integrated into the belt to meet specific operational requirements. These customized accessories and features enable the modular belt to adapt to unique industry needs and conveyor system configurations.

- Size and Dimensions:

The size and dimensions of modular belts can be customized to fit specific conveyor configurations. The individual modules can be easily cut or extended to achieve the desired length of the belt. Additional modules can be added or removed to adjust the width of the belt according to the available space or product handling requirements. This customization allows the modular belt to seamlessly integrate into existing conveyor systems or be tailored to fit unique conveyor layouts.

- Specialized Belting Solutions:

Some modular belt manufacturers offer specialized belting solutions for specific industries or applications. These customized solutions are designed to address the unique challenges and requirements of particular industries, such as meat and poultry processing, baking, or automotive manufacturing. They may include features like antimicrobial coatings, high-temperature resistance, or specialized surface textures. These specialized belting solutions ensure that the modular belt is optimized for the specific industry or application, providing reliable and efficient performance.

In summary, modular belts can be customized for specific industries or conveyor configurations through material selection, module design, accessories and features, size and dimensions, and specialized belting solutions. This customization allows the modular belt to meet the unique needs of different industries and ensure optimal performance and functionality in diverse conveyor system applications.

Can you describe the various types and configurations of modular belts available in the market?

Modular belts are available in a wide range of types and configurations to suit different material handling needs and industry requirements. These belts are designed with various features, such as different module shapes, surface patterns, and materials. Here is an overview of the main types and configurations of modular belts available in the market:

- Flat Top Belts:

Flat top belts consist of flat, rectangular modules that interlock to form a continuous conveying surface. They provide a smooth and even transport platform for a wide range of products. Flat top belts are commonly used in industries such as food processing, packaging, and general manufacturing. They are suitable for handling items that require stable support, such as cartons, boxes, and containers.

- Flush Grid Belts:

Flush grid belts feature modules with a grid-like pattern of openings. The grid pattern allows for better airflow, drainage, and easy cleaning. These belts are often used in applications where liquids or debris need to be drained or removed from the conveying surface. Flush grid belts are commonly employed in industries such as food and beverage processing, where hygiene and cleanliness are critical.

- Raised Rib Belts:

Raised rib belts have modules with raised ribs or bars running along the length of the belt. The raised ribs provide additional grip, ensuring positive engagement with the conveyed products. These belts are suitable for inclined or declined conveying applications or when items need extra stability during transport. Raised rib belts are commonly used in industries such as incline/decline transportation, bakery, and meat processing.

- Mold to Width Belts:

Mold to width belts are designed to be easily and precisely customized to fit specific conveyor widths. They consist of modules that can be individually removed or added to achieve the desired belt width. Mold to width belts offer flexibility in configuring conveyor systems and can be adapted to changing production needs. These belts are commonly used in industries that require frequent belt width adjustments or when retrofitting existing conveyor systems.

- Open Grid Belts:

Open grid belts feature a grid-like pattern of open areas between the modules. The open design allows for good airflow and drainage, making these belts suitable for applications where cooling, drying, or drainage is required. Open grid belts are commonly used in industries such as food processing, cooling processes, and drying applications.

- Perforated Belts:

Perforated belts have modules with perforations or holes throughout the surface. The perforations allow for better drainage, airflow, and visibility. These belts are often used in applications where liquids or small particles need to be drained or filtered. Perforated belts are commonly employed in industries such as food processing, sorting, and wastewater treatment.

- Flighted Belts:

Flighted belts have modules with integrated flights or cleats along the conveying surface. The flights help to contain and elevate products during transport, preventing them from sliding or falling off the belt. Flighted belts are used in applications where inclined or vertical conveying is required, such as in bulk handling or incline/decline transportation. They are commonly employed in industries such as agriculture, mining, and bulk material handling.

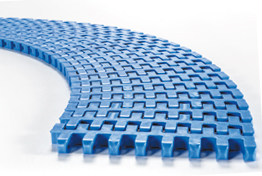

- Radius Belts:

Radius belts are designed to navigate tight curves or bends in conveyor systems. They feature modules with a curved shape that allows the belt to smoothly transition around corners. Radius belts are commonly used in industries where space is limited or when conveyor systems need to follow complex layouts. They are often found in industries such as packaging, bottling, and material handling in confined spaces.

- Wire Mesh Belts:

Wire mesh belts are composed of metal modules or links, typically made of stainless steel. These belts offer high strength, durability, and excellent heat resistance. Wire mesh belts are used in applications where heavy loads, high temperatures, or strict sanitation requirements are present. They are commonly employed in industries such as automotive manufacturing, heat-treatment processes, and industrial ovens.

These are some of the main types and configurations of modular belts available in the market. Each type offers specific features and benefits, allowing for customized solutions in various industries and material handling applications.

editor by CX 2024-04-16