Product Description

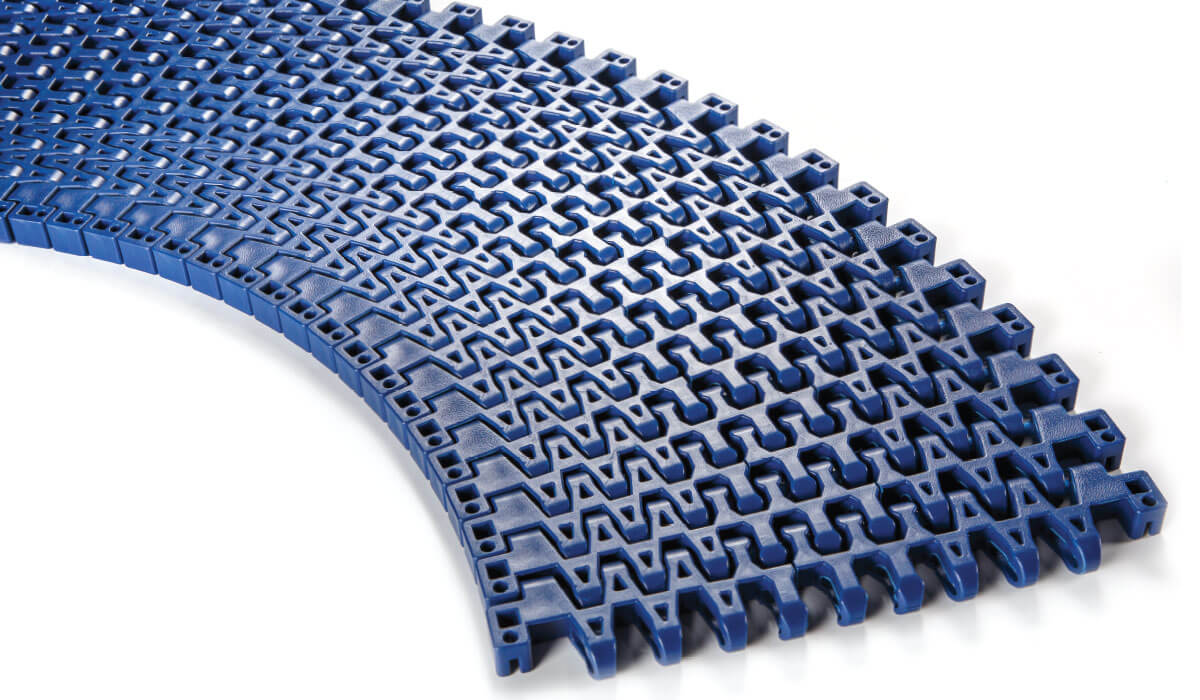

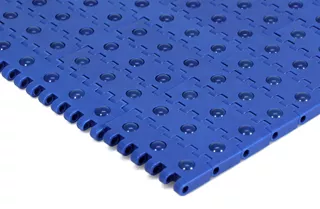

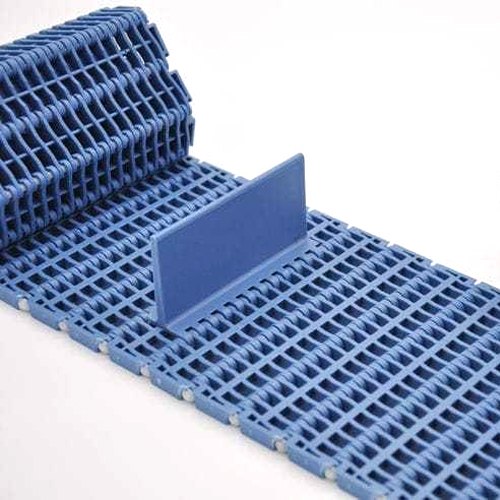

Hairise 2401 Radius Good Quality Flush Grid Modular Conveyor Belt

| Name | Har2401 flush gird modular belt |

| Pitch | 25.4mm |

| Thickness | 12.7mm |

| Open area | 40% |

| Material | POM/PP |

| Brand | Hairise |

| Place | ZheJiang city,China (ZheJiang port) |

| Business Type | Manufacturer |

Advantages of the CZPT modular belt conveyors:

1 this modular conveyor belt are convenient to assembly and maintain

2.All color could be available

2.this modular conveyor belt can bear High mechanical strength

3.this modular conveyor belt has Excellent product handling performance

4. these modular conveyor belts are wear resistance and Oil Resistant

5.we are a professional conveyor system manufacturer, our product line contains modular belt, slat top chain, conveyor spare parts, conveyor system.

6.we can provide good after-sale service.

7.every product can be customized

Application:

Bakery, Dairy, Fruit, and Vegetable

We have extensive experience in developing specialized solutions tailored to the needs of many different Bakery industry segments: bread and bun, fresh pastry (oven and fried pastry), pizza, pasta (fresh and dry), frozen bread, frozen pastry, cookies, and crackers, with our material handling equipment conveyor systems conveyor plastic modular belt conveyor you can get surprised!

Meat Poultry Seafood

With belts and accessories designed to meet the specific needs of fruit and vegetable processing and packaging applications, Hairise is committed to helping customers achieve their operational and business goals.

Hairise continues to develop new and better ways for customers to increase throughput efficiency, improve sanitation, and reduce the costs of belt ownership.

Material handling equipment conveyor systems conveyor plastic modular belt conveyor technology to meet the specific challenges of seafood processors.

Ready Meals

Ready meal customers who equip their lines with CZPT Industrial plastic slat table top food grade conveyor chain realize many critical benefits, including:

·Reduced sanitation costs and improved food safety

·Improved line efficiency and maintain product alignment

·Reduced unscheduled downtime and reduced labor needs

Mu Jia Automation Technology(ZheJiang ) Co, Ltd.

MuJia is an integrated company engaged in the R&D, manufacture and sale of slat top chain,modular belt,conveyor system and other related components almost 20 years. Insisting on the operation principle of “Quality Based and Service First”, our company has won a high reputation through many years of development. We also cooperate with some well-known domestic and overseas enterprises.

Our head office located in ZheJiang ,new factory located in ZheJiang province,covers an areas of 15,000 square meter,there are 3 main buildings:office building,conveyor assembly workshop and production workshop.More than 10 machines for producing,many hundreds of item models for meeting customer variety requirements.Our main products are modular belt,slat top chain,flexible chain,conveyor system,comb,rail,sprocket and other conveyor related components.They are widely used in food, soft drink, packaging & manufacturing, tobacco, medicine & chemical, electronics, automobiles and logistics industries.

Our modular belt and conveyor equipments sell to every corners of country, with more than 200 primary agents and 400 special service centers. Besides, we exported to more than 40 countries and regions, such as Africa, Latin America, Southeast Asia, Middle East, Central Asia Europe and America and etc. What’s more, CZPT was proud to the ZheJiang equity trading custody center successfully Listed since 2008.

At the end of February, 2016, the covers area of 35,00 square meters CZPT headquarter Phase II Park was built up and used, which annual production capacity could be 10,000 loaders, modular belt conveyor and 3,000 conveyor systems .

Then the north base of CZPT started siince early December of 2016, can offer 10,000 conveyor, plastic modular belt and 13,000 flexible chains piece year. The factory is located in Haian District, HangZhou City, ZheJiang Province, covers 300,000 square meters.

Orients to “Technologic Innovation, Industrial Upgrade, Managerial Optimization, Brand Leap” business policy, insist on the core value of “Integrity, Studious, Innovation, Courageous, Appreciate”, Hairisebelt will constantly optimize the industrial layout, improve the governance structure, boost the pace of construction, to create a century-old industry CZPT brand.

Q1. Where is your factory located? How can I visit there?

A: All our clients, from home or abroad, are warmly welcomed to visit us. Before you visit our company, we can connect by phone! Our company is located in ZheJiang , China, near the ZheJiang Xihu (West Lake) Dis.ao International Airport. And our factory is in ZheJiang HangZhou, we will arrange cars to there.

Q2. I don’t know what belt I currently use. Can you help me identify my belt?

A: Our online belt identifier can help you narrow down the series and style of your current belt. If you need more specific information on plastic conveyor chain belt parts manufacturers, contact me freely for plastic chains/ belts/ PU/PVC/Rubber belts/ other components and conveyors.

Q3. What can you do If the products were broken?

(1) If goods were broken once you bought from me,I would replace them freely according to the proven photos.

(2) If the goods were broken when you used, we could provide 5 year quality guarantee for plastic conveyor chain belt parts manufacturers under common working environment.

Q4. Does CZPT provide PDF files of products?

A: Yes, in our download center you can find PDF files for a large number of our products.If you can not find what you are looking for, send me your request by email or contact me on Wechat or Whatsapp freely.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Structure: | Belt Conveyor |

|---|---|

| Material: | Plastic |

| Material Feature: | Oil Resistant, Heat Resistant, Fire Resistant |

| Application: | Chemical Industry, Grain Transport, Mining Transport, Power Plant |

| Condition: | Used |

| Model No: | Har2401 |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What are the key considerations for the installation and operation of modular belts in industrial settings?

Installing and operating modular belts in industrial settings requires careful consideration of various factors to ensure optimal performance and longevity. Here are key considerations for the installation and operation of modular belts:

- System Design and Layout:

Before installing modular belts, it is crucial to design the conveyor system and layout properly. Consider factors such as the desired throughput, product characteristics, space constraints, and ergonomic considerations. Ensure that the system design allows for smooth product flow, efficient material handling, and easy accessibility for maintenance and cleaning.

- Belt Selection:

Choose the appropriate modular belt based on the specific application requirements. Consider factors such as the product type, weight, size, and operating conditions. Select a belt with the right material composition, surface pattern, and module design to ensure optimal performance, durability, and hygiene standards.

- Installation Guidelines:

Follow the manufacturer’s installation guidelines carefully. Modular belts typically come with specific instructions for assembly, sprocket engagement, and tensioning. Ensure that the belt is installed with proper alignment and tension to avoid premature wear, slippage, or tracking issues. It is important to use the recommended equipment and tools during installation to prevent damage to the belt or conveyor components.

- Belt Tracking and Tensioning:

Maintaining proper belt tracking and tension is essential for smooth and efficient operation. Regularly monitor the belt tracking to ensure it stays aligned and centered on the conveyor. Adjust the tracking mechanisms or use tracking devices as needed. Additionally, maintain the appropriate belt tension to prevent slippage or excessive wear. Follow the manufacturer’s recommendations for tensioning and use tensioning devices or systems if required.

- Maintenance and Cleaning:

Implement a regular maintenance and cleaning routine for the modular belts. Remove any debris, product residue, or contaminants that may accumulate on the belt surface or within the conveyor system. Follow proper cleaning procedures using suitable cleaning agents and tools. Avoid using harsh chemicals that can damage the belt material. Regularly inspect the belt for signs of wear, damage, or abnormal behavior and address any issues promptly to prevent breakdowns or product contamination.

- Safety Considerations:

Prioritize safety during installation and operation. Ensure that all safety guards, emergency stop buttons, and other safety features are properly installed and functional. Provide proper training to operators on the safe operation, maintenance, and troubleshooting procedures for the modular belt system. Regularly inspect the system for any potential safety hazards and address them promptly to create a safe working environment.

- Continuous Monitoring and Optimization:

Implement a system for continuous monitoring and optimization of the modular belt system. Utilize sensors or monitoring devices to track belt performance, temperature, vibration, or other relevant parameters. Analyze the collected data to identify any potential issues or areas for improvement. Regularly review and optimize the system settings, such as belt speed, tension, or tracking, based on the operational requirements and performance feedback.

By considering these key factors during the installation and operation of modular belts in industrial settings, companies can ensure efficient, reliable, and safe material handling processes while maximizing the lifespan and performance of the modular belt system.

How do modular belts contribute to the flexibility and adaptability of conveyor systems?

Modular belts play a crucial role in enhancing the flexibility and adaptability of conveyor systems. Their unique design and construction offer several advantages that enable conveyor systems to be easily customized and adapted to meet specific operational requirements. Here’s how modular belts contribute to the flexibility and adaptability of conveyor systems:

- Modular Design:

Modular belts are composed of individual modules or links that are interconnected to form a continuous belt. These modules are typically made of plastic materials such as polypropylene, polyethylene, or acetal. The modular design allows for easy assembly and disassembly of the belt, facilitating quick modifications or replacements when needed. Conveyor systems can be easily reconfigured or expanded by adding or removing modules, enabling flexibility in adapting to changing production needs or layouts.

- Customizable Length and Width:

Modular belts can be customized to specific lengths and widths, allowing conveyor systems to be tailored to the available space and operational requirements. The individual modules can be easily cut to the desired length, and additional modules can be added or removed to adjust the width of the belt. This flexibility in sizing enables efficient utilization of space and facilitates integration into existing production lines or facilities without major modifications.

- Configurable Conveyor Layouts:

Modular belts offer versatility in configuring conveyor layouts to suit different applications. The interlocking modules allow for smooth movement around curves and bends, enabling the creation of curved or spiral conveyors. This flexibility in conveyor design facilitates the efficient use of floor space and enables the movement of products along complex paths. Conveyor systems can be easily adapted to fit within existing production environments or optimize material flow in specific processes.

- Specialized Modules and Accessories:

Modular belts offer a wide range of specialized modules and accessories that enhance the adaptability of conveyor systems. Various module designs are available to cater to specific product handling requirements, such as modules with high friction surfaces for inclines or declines, cleated modules for vertical lifting, or roller-top modules for smooth product transfers. Additionally, accessories such as side guards, flights, and guide rails can be easily integrated into the modular belt to accommodate different product sizes, shapes, or orientations.

- Easy Integration with Other Conveyor Components:

Modular belts are designed to seamlessly integrate with other conveyor components, such as drive systems, idlers, and sprockets. The modular nature of the belt allows for simple connection to these components, enabling easy installation, maintenance, and replacement. This compatibility with other conveyor parts simplifies system modifications or upgrades, making it easier to adapt the conveyor to changing production needs or accommodate different types of materials.

- Application-Specific Features:

Modular belts offer application-specific features that contribute to the adaptability of conveyor systems. For example, there are modular belts designed for high-speed applications, heavy-duty applications, or applications that require low back-pressure accumulation. These specialized belts ensure that the conveyor system can handle specific material characteristics, production rates, or operational requirements, allowing for seamless integration into diverse industrial environments.

Overall, modular belts provide the flexibility and adaptability necessary for conveyor systems to meet the unique needs of different industrial applications. Their modular design, customizable dimensions, configurable layouts, specialized modules, and easy integration with other components make them a versatile choice for optimizing material handling processes and adapting to changing production demands.

In what industries are modular belts commonly employed for material handling?

Modular belts find wide application in various industries where efficient and reliable material handling is essential. The versatility, durability, and customizable nature of modular belts make them suitable for diverse handling needs. Here are some industries where modular belts are commonly employed:

- Food and Beverage:

The food and beverage industry extensively utilizes modular belts for material handling. These belts are ideal for transporting food products, including baked goods, fruits, vegetables, meat, poultry, and packaged items. Modular belts with specialized surface patterns or coatings ensure gentle handling, prevent product damage, and meet hygiene requirements. They are also resistant to chemicals and can withstand washdown procedures, making them suitable for food processing and packaging applications.

- Packaging and Logistics:

Modular belts play a crucial role in the packaging and logistics industry. They are commonly used in conveyor systems for packaging, sorting, and distribution operations. Modular belts provide reliable transportation of items, such as boxes, cartons, bags, and parcels. The ability to customize the belt’s surface and accessories allows for efficient sorting, merging, and diverting of products. Modular belts also facilitate accumulation and indexing, enabling smooth flow control in packaging lines and distribution centers.

- Automotive and Manufacturing:

In the automotive and manufacturing industries, modular belts are employed for handling various components and assemblies. They are used in assembly lines, machining operations, and material transfer processes. Modular belts can handle heavy loads and provide precise positioning, ensuring smooth and efficient movement of automotive parts, machinery components, and other manufactured goods. The durability of modular belts allows them to withstand the demanding conditions of manufacturing environments.

- Airport and Baggage Handling:

Modular belts play a critical role in airport baggage handling systems. They are used to transport luggage and other items through conveyor systems, including check-in areas, security checkpoints, and baggage claim areas. Modular belts with low-friction surfaces and gentle handling characteristics ensure the safe and efficient movement of baggage, reducing the risk of damage. The ability to accommodate inclines, declines, and curves makes modular belts suitable for complex airport layouts and varying elevation changes.

- Pharmaceutical and Healthcare:

The pharmaceutical and healthcare industries rely on modular belts for material handling in various processes. Modular belts are used in pharmaceutical manufacturing, packaging, and distribution facilities. They provide a clean and hygienic solution for transporting medications, medical devices, and healthcare products. Modular belts with antimicrobial properties or easy-to-clean surfaces support the industry’s stringent hygiene standards. These belts also facilitate the precise positioning and handling of delicate or sensitive pharmaceutical products.

- E-commerce and Retail:

In the e-commerce and retail sectors, modular belts are utilized for efficient material handling in warehouses, fulfillment centers, and distribution hubs. They enable the movement of packages, boxes, and totes along conveyor systems, ensuring timely order fulfillment and shipping. Modular belts with high load capacities and customizable configurations allow for the handling of a wide range of products, from small items to larger merchandise. The modular design of these belts also enables easy integration with automated systems, such as barcode scanners and robotic pick-and-place systems.

- General Manufacturing:

Modular belts find applications in general manufacturing industries, including electronics, consumer goods, textiles, and more. They are used for material handling in assembly lines, testing processes, and product packaging. The flexibility and adaptability of modular belts make them suitable for diverse manufacturing environments and product types. Modular belts can handle both lightweight and heavy items, making them versatile for a wide range of manufacturing applications.

These are just a few examples of the industries where modular belts are commonly employed for material handling. The modular design, durability, and customizable features of these belts make them a preferred choice for efficient and reliable transportation of goods in various industrial sectors.

editor by CX 2024-04-16