Product Description

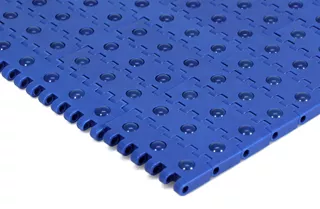

1000 Series Plastic Modular Conveyor Belt for manufacturing

Advantages:

1 This modular conveyor belt are convenient to assembly and maintain

2. This modular conveyor belt can bear High mechanical strength

3. This modular conveyor belt has Excellent product handling performance

4. This modular conveyor belt are wear resistance and Oil Resistant

5. We are professional conveyor system manufacturer,our product line contain: modular belt, slat top chain, conveyor spare parts, conveyor system.

6. We can provide good after-sale service.

7. Every products can be customized

Application :

Specifications:

| Belt type | Pitch(mm) | Material | Belt Weight kg/m2 |

Working load | Backflex radius |

| 1000-A | 25.4 | POM | 6.5 | 22000 | 25 |

| PP | 4.25 | 11000 | |||

| PE | 4.6 | 5000 |

Product display:

Exhibitions:

Our workshop:

Package delivery:

Company Introduction:

Xihu (West Lake) Dis. Xihu (West Lake) Dis. Industrial Co., Ltd., founded in 1998, is located in HangZhou. The company covers a total area of 14000 square meters. It is a high-tech enterprise integrating scientific research and development, engineering design, production and installation, and commissioning services.It is a set of independent research and development, production, processing, sales as 1 of the automation equipment and machinery manufacturers.

If you order from us, we are sure that you will be greatly satisfied with our products and the most competitive price.We are mainly majored in Conveyor Equipments for nearly 20 years so you can be relieved for our products. We are very looking forward to receive your any enquiries or orders. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | 1000 |

|---|---|

| Material: | Metal |

| Inside Material: | Plastic |

| Feature: | Oil-Resistant, Acid And Alkali Resistant, Tear-Resistant, Heat-Resistant, Cold-Resistant, Wear-Resistant |

| Tensile Strength: | Strong |

| Backflex Radius: | 25mm |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can modular belts be used in heavy-duty applications, such as mining or construction?

Yes, modular belts can be used in heavy-duty applications, including mining and construction. Here’s a detailed explanation:

Modular belts are designed to offer robust performance and durability, making them suitable for a wide range of industrial applications, including heavy-duty environments. In heavy-duty industries like mining and construction, where materials are often large, heavy, and abrasive, modular belts provide several advantages over traditional conveyor belt systems.

- Strength and Load Capacity:

Modular belts are engineered to handle heavy loads and withstand the demanding conditions encountered in mining and construction operations. They are constructed using high-strength materials, such as reinforced thermoplastics or metals, which offer excellent load-carrying capacity and resistance to impact and abrasion. This enables modular belts to transport heavy materials, such as ore, gravel, rocks, or construction aggregates, with ease and reliability.

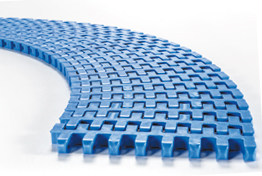

- Flexibility and Adaptability:

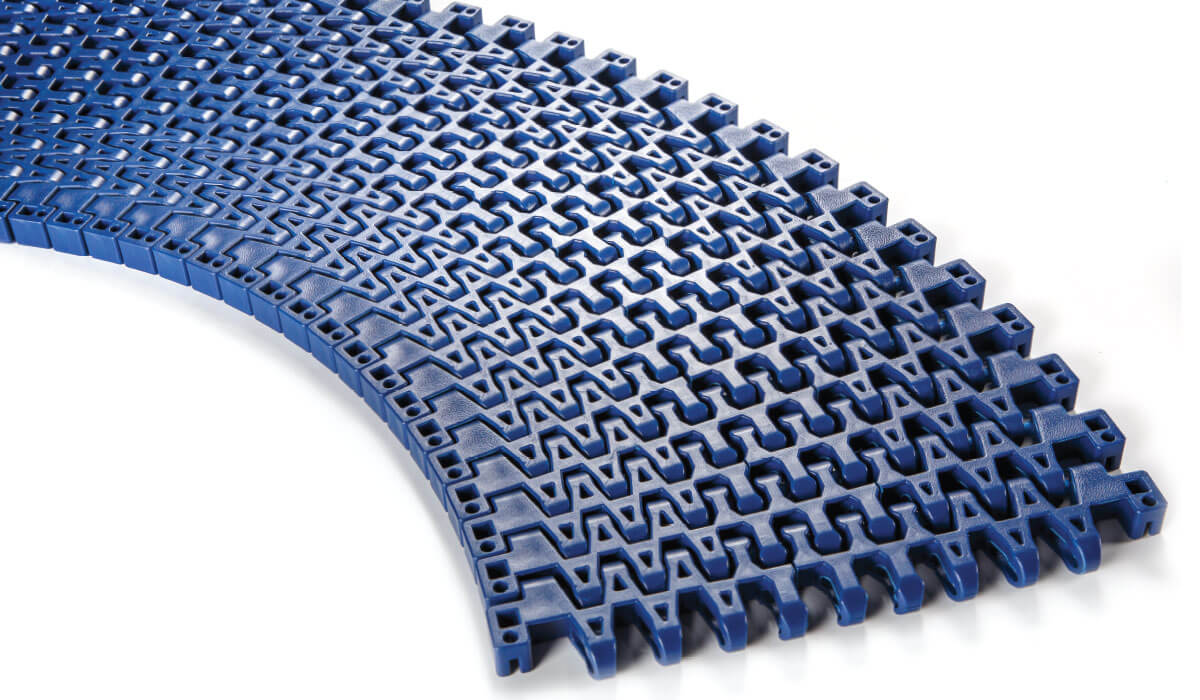

Modular belts exhibit flexibility and adaptability, which are essential in heavy-duty applications. The modular design allows for easy customization of the belt width, length, and configuration to accommodate specific material handling requirements. Belt modules can be easily added, removed, or reconfigured to adapt to changes in the production process or conveyor layout. This flexibility enables modular belts to fit into existing conveyor systems or be designed for unique applications in mining and construction, optimizing material flow and operational efficiency.

- Resistance to Wear and Tear:

Heavy-duty applications expose conveyor belts to harsh conditions, including abrasive materials, impact, and high levels of mechanical stress. Modular belts are designed to withstand such wear and tear, thanks to their rugged construction and specialized surface features. The modules often have reinforced or textured surfaces that enhance grip and prevent material slippage, reducing the risk of belt damage or product spillage. Additionally, modular belts are resistant to abrasion and tearing, ensuring prolonged service life in challenging mining and construction environments.

- Chemical and Moisture Resistance:

In certain mining and construction applications, conveyor belts may encounter chemicals, moisture, or other environmental factors that can degrade the belt material. Modular belts are available in chemically resistant materials, such as polyethylene or polypropylene blends, which can withstand exposure to various chemicals and moisture without significant deterioration. This chemical and moisture resistance ensures that modular belts maintain their structural integrity and performance even in harsh operating conditions.

- Easy Maintenance and Repairs:

Maintenance and repair requirements are inevitable in heavy-duty applications. Modular belts offer advantages in terms of maintenance and repairs. The modular design allows for quick and cost-effective repairs, as individual modules can be replaced without replacing the entire belt. This reduces downtime and minimizes production disruptions. Additionally, modular belts are generally easier to clean and sanitize, contributing to overall maintenance efficiency in heavy-duty environments.

In summary, modular belts can indeed be used in heavy-duty applications, including mining and construction. Their strength, load capacity, flexibility, resistance to wear and tear, chemical and moisture resistance, and ease of maintenance make them a viable choice for efficiently handling heavy materials and operating reliably in demanding industrial settings.

How does the maintenance of modular belts compare to traditional conveyor belt systems?

Maintenance requirements for modular belts differ from those of traditional conveyor belt systems. Here’s a comparison of the maintenance aspects between modular belts and traditional conveyor belt systems:

- Cleaning and Sanitation:

Both modular belts and traditional conveyor belt systems require regular cleaning and sanitation to maintain hygiene in industrial environments. However, modular belts are generally easier to clean due to their design. The individual modules can be easily removed or disassembled, allowing for thorough cleaning of the entire belt surface. This modular design facilitates access to hard-to-reach areas and reduces cleaning time. In contrast, traditional conveyor belts may have more complex structures, with interwoven or solid surfaces that can be challenging to clean effectively.

- Maintenance and Repairs:

Maintenance and repairs are common requirements for both modular belts and traditional conveyor belt systems. The maintenance tasks typically involve inspecting the belt for wear, damage, or misalignment, and replacing or repairing any damaged components. Modular belts are designed for easy maintenance, as individual modules can be replaced without the need to replace the entire belt. This modular feature allows for quick and cost-effective repairs, reducing downtime in production. Traditional conveyor belt systems, on the other hand, may require more extensive maintenance and repairs, as they often involve continuous belts that need to be replaced as a whole if damaged.

- Belt Tensioning:

Belt tensioning is an important maintenance aspect for both modular belts and traditional conveyor belt systems. Proper belt tension ensures optimal performance and prevents slippage or misalignment. Modular belts typically have tensioning mechanisms that allow for easy adjustment of belt tension. This adjustment can be done without removing the belt from the conveyor, simplifying the maintenance process. Traditional conveyor belt systems may also have tensioning mechanisms, but they may require more labor-intensive procedures to adjust the belt tension.

- Belt Replacement:

When it comes to belt replacement, modular belts offer advantages over traditional conveyor belt systems. Modular belts are designed with individual modules that can be easily replaced if damaged or worn out. This selective replacement minimizes costs and reduces downtime since only the affected modules need to be replaced. In contrast, traditional conveyor belts are usually continuous belts that need to be replaced entirely when they reach the end of their lifespan or suffer significant damage. This replacement process can be more time-consuming and costly.

- Customization and Adaptability:

Modular belts often provide more customization and adaptability options compared to traditional conveyor belt systems. The modular design allows for easy customization of belt width, length, and configuration to fit different conveyor layouts and specific application requirements. This flexibility simplifies maintenance and replacement processes, as modules can be easily added, removed, or reconfigured. Traditional conveyor belt systems may have limited customization options, requiring more complex adjustments or modifications during maintenance or replacement.

In summary, modular belts generally offer advantages in terms of maintenance compared to traditional conveyor belt systems. They are easier to clean and sanitize, facilitate quick and cost-effective repairs, allow for easy belt tension adjustment, offer selective module replacement, and provide customization and adaptability options. These maintenance benefits contribute to reducing downtime, improving operational efficiency, and minimizing maintenance costs in industrial conveyor systems.

What are modular belts, and how are they used in industrial applications?

Modular belts are conveyor belts composed of individual interlocking modules or links. These modules are typically made of durable plastic materials, such as polypropylene or polyethylene, and feature a variety of surface patterns or configurations. Modular belts are widely used in industrial applications for their versatility, durability, and ease of maintenance. Here is an overview of modular belts and their uses in industrial settings:

- Structure and Design:

Modular belts consist of individual modules that are linked together to form a continuous belt. Each module has built-in hinges or connecting rods that allow for easy assembly and disassembly. The modules are usually flat or slightly curved, and their surface can be customized with different patterns, textures, or accessories to suit specific application requirements. The modular design provides flexibility in terms of belt width, length, and configuration, making it adaptable to various industrial applications.

- Material Handling:

One of the primary uses of modular belts in industrial applications is for material handling. They are commonly employed in conveyor systems for the transportation of goods, products, or components. Modular belts offer smooth and consistent movement, allowing for the efficient transfer of materials from one point to another. They can handle a wide range of loads, from lightweight packages to heavy bulk materials, making them suitable for diverse industries such as manufacturing, logistics, food processing, and automotive.

- Accumulation and Sorting:

Modular belts are often utilized in accumulation and sorting applications. The interlocking modules create a flat and even surface, which enables products to accumulate without interference. This feature is particularly useful in assembly lines or distribution centers, where items need to be temporarily stored or grouped before further processing or sorting. The modular design allows for easy integration with other equipment, such as sensors or diverters, to facilitate automated sorting or routing of products based on specific criteria.

- Inclined or Declined Transport:

Modular belts are well-suited for inclined or declined transport applications. The interlocking modules ensure that products remain stable and do not slide or roll during vertical or angled movement. This makes modular belts ideal for applications such as elevating or lowering products between different levels of a production facility or warehouse. The customizable surface patterns of the modules can provide additional grip or friction, further enhancing the belt’s ability to handle inclined or declined transport of goods.

- Hygienic and Sanitary Applications:

Modular belts are widely used in industries that require hygienic or sanitary conditions, such as the food and beverage or pharmaceutical sectors. The smooth and non-porous surface of modular belts is easy to clean and resistant to the accumulation of debris, moisture, or bacteria. They can withstand frequent washdowns or sanitization processes without compromising their structural integrity. Additionally, the modular design allows for quick and straightforward module replacement in case of damage or contamination.

- Specialized Applications:

Modular belts find applications in specialized industrial processes as well. For example, they are used in high-temperature environments, such as baking or heat-treatment ovens, where traditional conveyor belts may not be suitable. Modular belts can withstand elevated temperatures without deformation or degradation. They are also utilized in applications that require tight transfers or small product gaps, such as in the packaging industry, where precise positioning and spacing of products are crucial.

In summary, modular belts are conveyor belts composed of individual interlocking modules. They are used in various industrial applications, including material handling, accumulation and sorting, inclined or declined transport, hygienic and sanitary environments, and specialized processes. The modular design, durability, and ease of maintenance make them a versatile and reliable solution for diverse industrial sectors.

editor by CX 2024-03-29