Product Description

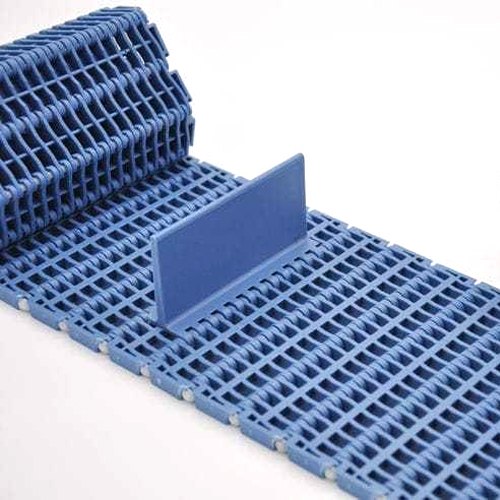

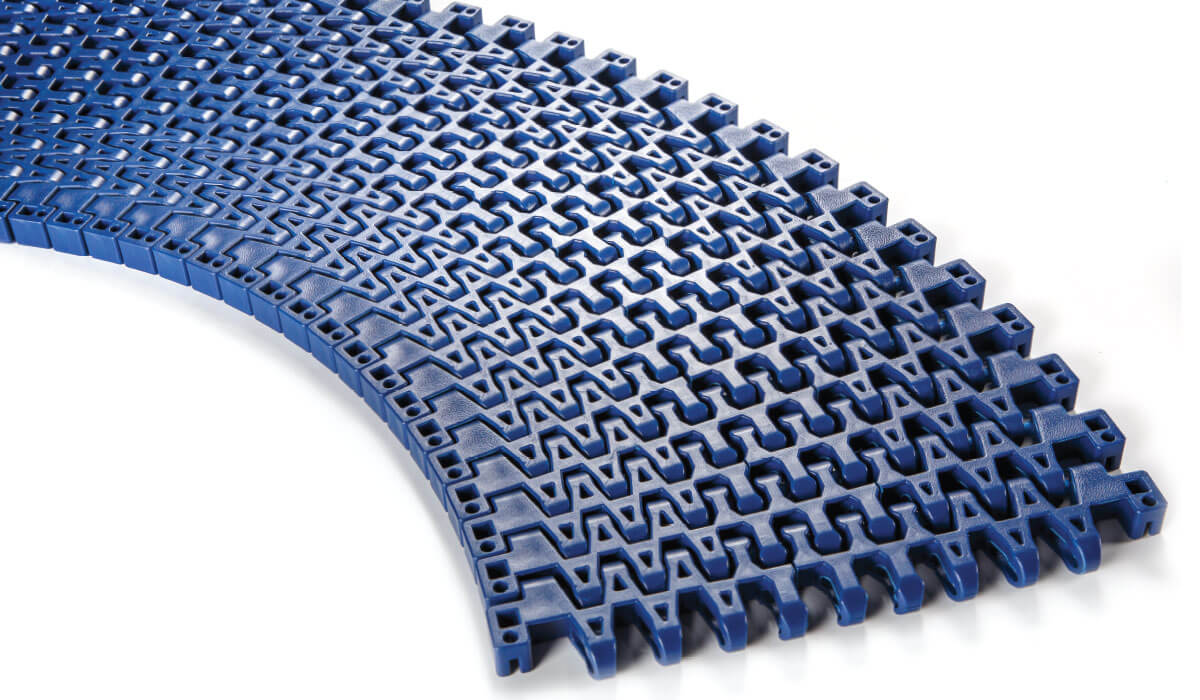

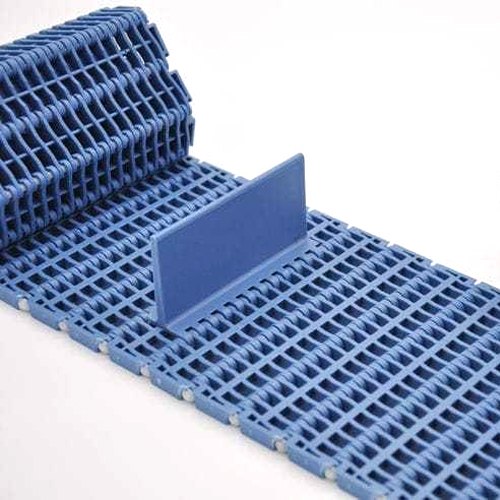

1000 Series Plastic Modular Conveyor Belt for manufacturing

Advantages:

1 This modular conveyor belt are convenient to assembly and maintain

2. This modular conveyor belt can bear High mechanical strength

3. This modular conveyor belt has Excellent product handling performance

4. This modular conveyor belt are wear resistance and Oil Resistant

5. We are professional conveyor system manufacturer,our product line contain: modular belt, slat top chain, conveyor spare parts, conveyor system.

6. We can provide good after-sale service.

7. Every products can be customized

Application :

Specifications:

| Belt type | Pitch(mm) | Material | Belt Weight kg/m2 |

Working load | Backflex radius |

| 1000-A | 25.4 | POM | 6.5 | 22000 | 25 |

| PP | 4.25 | 11000 | |||

| PE | 4.6 | 5000 |

Product display:

Exhibitions:

Our workshop:

Package delivery:

Company Introduction:

Xihu (West Lake) Dis. Xihu (West Lake) Dis. Industrial Co., Ltd., founded in 1998, is located in HangZhou. The company covers a total area of 14000 square meters. It is a high-tech enterprise integrating scientific research and development, engineering design, production and installation, and commissioning services.It is a set of independent research and development, production, processing, sales as 1 of the automation equipment and machinery manufacturers.

If you order from us, we are sure that you will be greatly satisfied with our products and the most competitive price.We are mainly majored in Conveyor Equipments for nearly 20 years so you can be relieved for our products. We are very looking forward to receive your any enquiries or orders. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | 1000 |

|---|---|

| Material: | Metal |

| Inside Material: | Plastic |

| Feature: | Oil-Resistant, Acid And Alkali Resistant, Tear-Resistant, Heat-Resistant, Cold-Resistant, Wear-Resistant |

| Tensile Strength: | Strong |

| Backflex Radius: | 25mm |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do modular belts contribute to reducing friction and energy consumption in conveyor systems?

Modular belts play a significant role in reducing friction and energy consumption in conveyor systems. Here’s an in-depth explanation:

In traditional conveyor belt systems, friction between the belt and the conveyor components can result in energy losses and increased power requirements. Modular belts offer several features that help minimize friction and reduce energy consumption in conveyor systems.

- Low Coefficient of Friction:

Modular belts are engineered with materials that have a low coefficient of friction, meaning they have a reduced tendency to generate resistance or stickiness when in contact with other surfaces. This property allows for smoother movement of the belt along the conveyor system, resulting in less friction and reduced energy consumption. The low coefficient of friction also contributes to improved product flow and reduced product damage during conveying.

- Specialized Surface Patterns:

Modular belts often feature specialized surface patterns or textures that further reduce friction and improve belt performance. These patterns can include raised ribs, dimples, or microstructures that create air gaps or channels between the belt and the conveyed product. These air gaps act as a cushion, reducing surface contact and friction between the belt and the product. By minimizing frictional resistance, modular belts allow for smoother product movement and require less energy to drive the conveyor system.

- Efficient Sprocket Engagement:

Modular belts utilize sprockets to drive and guide the belt along the conveyor system. The design and engagement of the sprockets play a crucial role in reducing friction and energy consumption. Modern modular belts feature optimized sprocket engagement, where the sprocket teeth are designed to match the shape and pitch of the belt modules precisely. This precise engagement ensures minimal slippage and friction between the sprocket and the belt, resulting in efficient power transmission and reduced energy losses.

- Precise Belt Tracking:

Accurate belt tracking is essential for minimizing friction and energy consumption in conveyor systems. Modular belts are designed to maintain stable and precise tracking, reducing the risk of belt misalignment or rubbing against the conveyor components. This precise tracking minimizes unnecessary friction and wear, ensuring optimal belt performance and energy efficiency. Some modular belt systems incorporate automatic tracking technologies, such as sensors or tracking devices, to continually monitor and adjust the belt position, further enhancing tracking accuracy and reducing energy losses.

- Reduced Belt Tension Requirements:

Modular belts generally require lower tension compared to traditional conveyor belts. The low tension requirements contribute to reduced friction and energy consumption. Lower belt tension results in less strain on the conveyor components, such as bearings and drives, reducing frictional resistance and power requirements. Additionally, reduced tension helps extend the lifespan of the belt and the conveyor system, as it minimizes stress and wear on the components.

By incorporating low friction materials, specialized surface patterns, efficient sprocket engagement, precise belt tracking, and lower tension requirements, modular belts contribute to reducing friction and energy consumption in conveyor systems. These features improve overall operational efficiency, reduce power costs, and promote sustainability by minimizing energy waste.

Can you provide examples of products or machinery that use modular belts for conveying materials?

Modular belts are widely used in various industries and applications for conveying materials. They are employed in a range of products and machinery to ensure efficient and reliable material handling. Here are some examples of products and machinery that utilize modular belts:

- Food Processing Equipment:

In the food processing industry, modular belts are extensively used in equipment such as conveyors, sorting systems, and packaging machines. They are employed to transport a wide range of food products, including baked goods, fruits and vegetables, meat and poultry, dairy products, and packaged snacks. Modular belts help ensure hygienic and gentle handling of food items, as well as facilitate efficient product flow during processing, sorting, and packaging operations.

- Beverage Bottling Lines:

In beverage bottling plants, modular belts are commonly integrated into conveyor systems for the transportation of bottles, cans, and other containers. They are utilized in various stages of the bottling process, including filling, capping, labeling, and packaging. Modular belts provide a smooth and reliable conveying surface, allowing for seamless movement of containers and ensuring precise alignment during filling and capping operations.

- Automotive Manufacturing:

In automotive manufacturing facilities, modular belts are utilized in assembly lines and material handling systems. They are employed to convey various automotive components, such as engines, transmissions, chassis parts, and interior components. Modular belts offer flexibility in configuring conveyor systems to accommodate different assembly processes and part sizes. They help streamline production and facilitate the efficient transfer of components between workstations.

- Pharmaceutical Production:

In the pharmaceutical industry, modular belts play a crucial role in conveying materials during the production of medications and medical devices. They are used in processes such as tablet and capsule handling, packaging, and labeling. Modular belts provide a clean and hygienic conveying surface, ensuring compliance with strict regulatory requirements. They enable precise positioning of pharmaceutical products during packaging and facilitate efficient material flow in pharmaceutical production lines.

- E-commerce and Logistics:

In e-commerce warehouses, distribution centers, and logistics facilities, modular belts are employed in conveyor systems for the sorting, merging, and transportation of packages and parcels. They are used to handle a wide variety of products, including boxes, cartons, totes, and polybags. Modular belts offer a reliable and flexible conveying solution in high-throughput environments, enabling efficient order fulfillment and smooth material flow in the logistics and supply chain industry.

- Packaging Machinery:

Modular belts are extensively integrated into packaging machinery, such as form-fill-seal machines, carton erectors, case packers, and palletizers. They are used to transport packaging materials, primary and secondary packaging, and finished products. Modular belts help ensure precise and synchronized movement of packages during the packaging process, optimizing productivity and minimizing product damage.

- Agricultural Equipment:

In the agricultural sector, modular belts are utilized in equipment such as harvesters, seed processing machines, and sorting systems. They are employed to handle crops, seeds, and other agricultural products during harvesting, processing, and packaging operations. Modular belts provide reliable conveying surfaces that can withstand outdoor conditions and facilitate the efficient movement of agricultural materials.

- Material Handling in Warehouses:

Modular belts are used in warehouse material handling systems, including conveyor systems for order picking, sorting, and distribution. They are employed to transport a wide range of products, including packages, cartons, and bins. Modular belts offer customization options to meet specific warehouse requirements, such as the ability to handle different product sizes and weights, adapt to varying layouts, and provide reliable and efficient material flow.

These are just a few examples of the many products and machinery that utilize modular belts for conveying materials. The versatility, reliability, and customization options of modular belts make them a popular choice in various industries where efficient and precise material handling is essential.

In what industries are modular belts commonly employed for material handling?

Modular belts find wide application in various industries where efficient and reliable material handling is essential. The versatility, durability, and customizable nature of modular belts make them suitable for diverse handling needs. Here are some industries where modular belts are commonly employed:

- Food and Beverage:

The food and beverage industry extensively utilizes modular belts for material handling. These belts are ideal for transporting food products, including baked goods, fruits, vegetables, meat, poultry, and packaged items. Modular belts with specialized surface patterns or coatings ensure gentle handling, prevent product damage, and meet hygiene requirements. They are also resistant to chemicals and can withstand washdown procedures, making them suitable for food processing and packaging applications.

- Packaging and Logistics:

Modular belts play a crucial role in the packaging and logistics industry. They are commonly used in conveyor systems for packaging, sorting, and distribution operations. Modular belts provide reliable transportation of items, such as boxes, cartons, bags, and parcels. The ability to customize the belt’s surface and accessories allows for efficient sorting, merging, and diverting of products. Modular belts also facilitate accumulation and indexing, enabling smooth flow control in packaging lines and distribution centers.

- Automotive and Manufacturing:

In the automotive and manufacturing industries, modular belts are employed for handling various components and assemblies. They are used in assembly lines, machining operations, and material transfer processes. Modular belts can handle heavy loads and provide precise positioning, ensuring smooth and efficient movement of automotive parts, machinery components, and other manufactured goods. The durability of modular belts allows them to withstand the demanding conditions of manufacturing environments.

- Airport and Baggage Handling:

Modular belts play a critical role in airport baggage handling systems. They are used to transport luggage and other items through conveyor systems, including check-in areas, security checkpoints, and baggage claim areas. Modular belts with low-friction surfaces and gentle handling characteristics ensure the safe and efficient movement of baggage, reducing the risk of damage. The ability to accommodate inclines, declines, and curves makes modular belts suitable for complex airport layouts and varying elevation changes.

- Pharmaceutical and Healthcare:

The pharmaceutical and healthcare industries rely on modular belts for material handling in various processes. Modular belts are used in pharmaceutical manufacturing, packaging, and distribution facilities. They provide a clean and hygienic solution for transporting medications, medical devices, and healthcare products. Modular belts with antimicrobial properties or easy-to-clean surfaces support the industry’s stringent hygiene standards. These belts also facilitate the precise positioning and handling of delicate or sensitive pharmaceutical products.

- E-commerce and Retail:

In the e-commerce and retail sectors, modular belts are utilized for efficient material handling in warehouses, fulfillment centers, and distribution hubs. They enable the movement of packages, boxes, and totes along conveyor systems, ensuring timely order fulfillment and shipping. Modular belts with high load capacities and customizable configurations allow for the handling of a wide range of products, from small items to larger merchandise. The modular design of these belts also enables easy integration with automated systems, such as barcode scanners and robotic pick-and-place systems.

- General Manufacturing:

Modular belts find applications in general manufacturing industries, including electronics, consumer goods, textiles, and more. They are used for material handling in assembly lines, testing processes, and product packaging. The flexibility and adaptability of modular belts make them suitable for diverse manufacturing environments and product types. Modular belts can handle both lightweight and heavy items, making them versatile for a wide range of manufacturing applications.

These are just a few examples of the industries where modular belts are commonly employed for material handling. The modular design, durability, and customizable features of these belts make them a preferred choice for efficient and reliable transportation of goods in various industrial sectors.

editor by CX 2024-03-29