Product Description

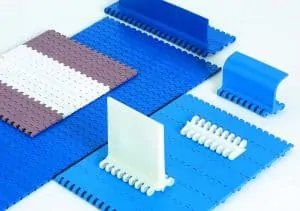

Item name: 1″ Pitch Flush Grid M2533 Plastic Modular Belt

Specifications:

1. Belt pitch: 25.4mm

2. Open area: 35%

3. Assembling method: Connected with rods

4. Good quality and factory price

5. Excellent for cooling and draining

Plastic Modular Belt

Plastic Flush Grid Belt

Modular Conveyor Belt

Modular Conveyor System

Modular Belting

Belt Conveyor

Our products with good quality and reasonable price can be applied in many areas including can, crate, container, meat, beverage, dairy industries and so on.

We are 1 of the most competitive manufacturers in China on plsatic conveyor chain and belts. The products have been exported to many countries including India, Australia, South Africa and so on.

Our Mission: Satisfy customer with reasonable price, reliable quality and timely delivery.

Our Vision: Develop more and more new products to satisfy our clients’ requirements.

We are sure your any inquiry or requirement will get our prompt attention.

| Belt type | Material | Temperature range | Working load(max.) | Weight | Backflex radius(min.) | |

| dry | wet | N/m(21ºC) | kg/m² | mm | ||

| POM | 4 to 80 | 4 to 65 | 18000 | 7.1 | 25 | |

| M2533 | PP | 5 to 105 | 5 to 105 | 14000 | 4.6 | 25 |

| PE | -46 to +66 | -46 to +66 | 8000 | 5.1 | 25 | |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Modular Conveyor System |

|---|---|

| Material: | POM, PP or PE |

| Belt Pitch: | 25.4mm |

| Open Area: | 35% |

| Assembling Method: | Connected with Rods |

| Condition: | New |

| Samples: |

US$ 0.1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Are there sustainability aspects associated with the use of modular belts in material handling systems?

Yes, there are sustainability aspects associated with the use of modular belts in material handling systems. Here’s a detailed explanation:

The adoption of modular belts in material handling systems brings several sustainability benefits, addressing environmental, social, and economic aspects of sustainability.

- Resource Efficiency:

Modular belts are designed to optimize resource efficiency during their production and use. The manufacturing process of modular belts has become more environmentally friendly, with advancements in materials and production techniques. Manufacturers are increasingly utilizing recycled materials in the production of modular belts, reducing the demand for virgin resources. Additionally, modular belts often have a longer service life compared to traditional conveyor belts, reducing the frequency of replacements and the associated resource consumption.

- Energy Efficiency:

Modular belts contribute to energy efficiency in material handling systems. Their low friction characteristics and optimized design features minimize energy losses during operation. Reduced friction between the belt and conveyor components results in lower power requirements for driving the belt, leading to energy savings. The use of precise sprocket engagement and accurate belt tracking also helps to optimize power transmission and minimize energy waste. Overall, the energy efficiency of modular belts contributes to lower operational costs and reduced environmental impact.

- Waste Reduction:

Modular belts are designed for durability and longevity, resulting in reduced waste generation. Their robust construction and resistance to wear and tear extend their service life, reducing the frequency of belt replacements. Moreover, modular belts are often repairable, with the ability to replace individual modules or segments instead of replacing the entire belt. This repairability reduces waste generation and promotes a more sustainable approach to maintenance and replacement in material handling systems.

- Hygiene and Cleanability:

Hygiene is a significant aspect of sustainability in industries such as food processing and pharmaceuticals. Modular belts are designed with cleanability in mind, featuring smooth surfaces and reduced crevices where contaminants can accumulate. This design minimizes the risk of bacterial growth and improves food safety compliance. Additionally, some modular belts incorporate antimicrobial additives that further enhance hygiene and reduce the need for chemical cleaning agents. The improved cleanability of modular belts contributes to sustainable operations by ensuring product integrity, reducing waste due to contamination, and minimizing the use of cleaning chemicals.

- Adaptability and Flexibility:

Modular belts offer adaptability and flexibility in material handling systems, contributing to sustainability. Their modular design allows for easy customization and reconfiguration, enabling efficient use of space and resources. Modular belts can be easily integrated into existing conveyor systems or designed for unique applications, optimizing material flow and reducing the need for extensive system modifications or new installations. This adaptability and flexibility result in resource savings and increased operational efficiency, aligning with sustainable practices.

- Recyclability:

Many modular belts are made from recyclable materials, contributing to the circular economy. At the end of their service life, modular belts can be recycled and processed into new products, reducing waste and conserving resources. The recyclability of modular belts aligns with sustainable waste management practices and reduces the environmental impact associated with belt disposal.

In summary, the use of modular belts in material handling systems offers several sustainability aspects. These include resource efficiency, energy efficiency, waste reduction, improved hygiene and cleanability, adaptability and flexibility, and recyclability. By incorporating modular belts into their operations, companies can reduce their environmental footprint, lower energy consumption, minimize waste generation, and promote sustainable practices in material handling processes.

Can you provide examples of products or machinery that use modular belts for conveying materials?

Modular belts are widely used in various industries and applications for conveying materials. They are employed in a range of products and machinery to ensure efficient and reliable material handling. Here are some examples of products and machinery that utilize modular belts:

- Food Processing Equipment:

In the food processing industry, modular belts are extensively used in equipment such as conveyors, sorting systems, and packaging machines. They are employed to transport a wide range of food products, including baked goods, fruits and vegetables, meat and poultry, dairy products, and packaged snacks. Modular belts help ensure hygienic and gentle handling of food items, as well as facilitate efficient product flow during processing, sorting, and packaging operations.

- Beverage Bottling Lines:

In beverage bottling plants, modular belts are commonly integrated into conveyor systems for the transportation of bottles, cans, and other containers. They are utilized in various stages of the bottling process, including filling, capping, labeling, and packaging. Modular belts provide a smooth and reliable conveying surface, allowing for seamless movement of containers and ensuring precise alignment during filling and capping operations.

- Automotive Manufacturing:

In automotive manufacturing facilities, modular belts are utilized in assembly lines and material handling systems. They are employed to convey various automotive components, such as engines, transmissions, chassis parts, and interior components. Modular belts offer flexibility in configuring conveyor systems to accommodate different assembly processes and part sizes. They help streamline production and facilitate the efficient transfer of components between workstations.

- Pharmaceutical Production:

In the pharmaceutical industry, modular belts play a crucial role in conveying materials during the production of medications and medical devices. They are used in processes such as tablet and capsule handling, packaging, and labeling. Modular belts provide a clean and hygienic conveying surface, ensuring compliance with strict regulatory requirements. They enable precise positioning of pharmaceutical products during packaging and facilitate efficient material flow in pharmaceutical production lines.

- E-commerce and Logistics:

In e-commerce warehouses, distribution centers, and logistics facilities, modular belts are employed in conveyor systems for the sorting, merging, and transportation of packages and parcels. They are used to handle a wide variety of products, including boxes, cartons, totes, and polybags. Modular belts offer a reliable and flexible conveying solution in high-throughput environments, enabling efficient order fulfillment and smooth material flow in the logistics and supply chain industry.

- Packaging Machinery:

Modular belts are extensively integrated into packaging machinery, such as form-fill-seal machines, carton erectors, case packers, and palletizers. They are used to transport packaging materials, primary and secondary packaging, and finished products. Modular belts help ensure precise and synchronized movement of packages during the packaging process, optimizing productivity and minimizing product damage.

- Agricultural Equipment:

In the agricultural sector, modular belts are utilized in equipment such as harvesters, seed processing machines, and sorting systems. They are employed to handle crops, seeds, and other agricultural products during harvesting, processing, and packaging operations. Modular belts provide reliable conveying surfaces that can withstand outdoor conditions and facilitate the efficient movement of agricultural materials.

- Material Handling in Warehouses:

Modular belts are used in warehouse material handling systems, including conveyor systems for order picking, sorting, and distribution. They are employed to transport a wide range of products, including packages, cartons, and bins. Modular belts offer customization options to meet specific warehouse requirements, such as the ability to handle different product sizes and weights, adapt to varying layouts, and provide reliable and efficient material flow.

These are just a few examples of the many products and machinery that utilize modular belts for conveying materials. The versatility, reliability, and customization options of modular belts make them a popular choice in various industries where efficient and precise material handling is essential.

Are there specific applications where modular belts outperform other types of conveyor belts?

Yes, there are specific applications where modular belts outperform other types of conveyor belts. The unique features and advantages of modular belts make them particularly suitable for certain material handling requirements. Here are some applications where modular belts excel:

- Conveying Fragile Products:

Modular belts are well-suited for handling fragile products that require gentle transportation. The flat and even surface of modular belts minimizes product damage, such as breakage or deformation, during conveying. The customization options of modular belts, including the ability to add soft or low-friction inserts, further enhance the gentle handling of delicate items. Industries such as food, electronics, and pharmaceuticals often rely on modular belts to transport fragile products without compromising their integrity.

- Accumulation and Indexing:

Modular belts offer excellent functionality for accumulation and indexing applications. Accumulation refers to the temporary storage of products on the conveyor system, allowing for controlled release and smooth flow downstream. Modular belts with low back-pressure accumulation systems facilitate efficient accumulation, preventing product collisions and jams. Indexing, on the other hand, involves precise positioning of products for assembly, sorting, or packaging purposes. Modular belts with integrated indexing capabilities allow for accurate and repeatable positioning, ensuring reliable automation in various industries.

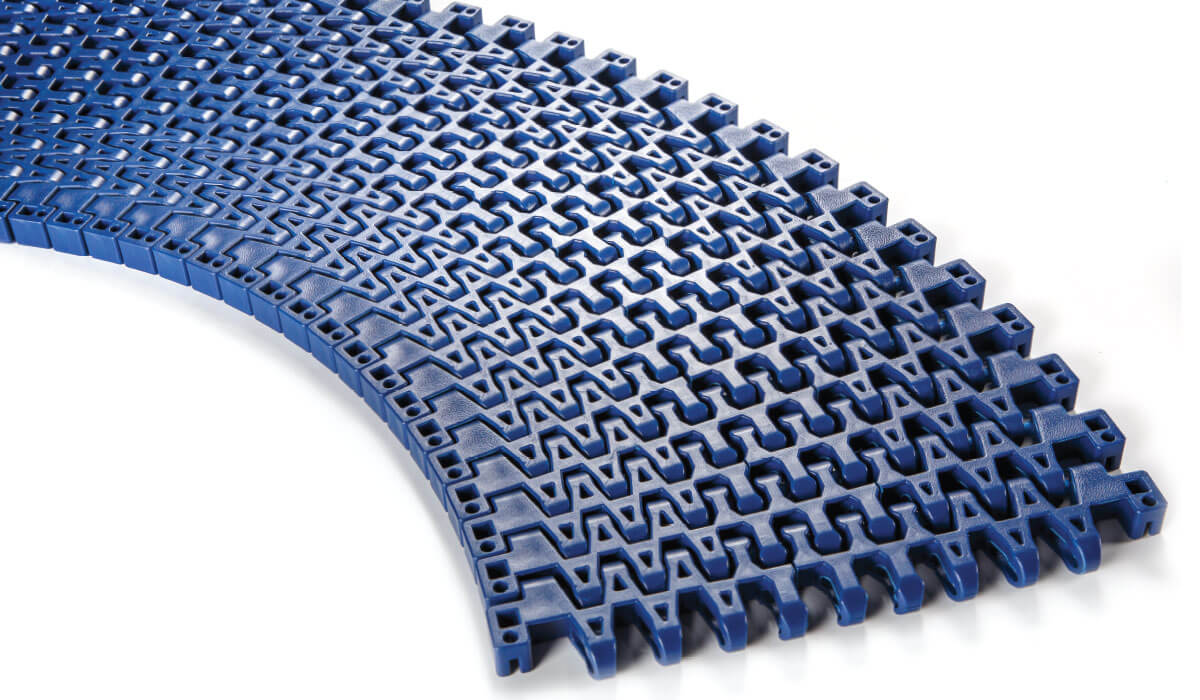

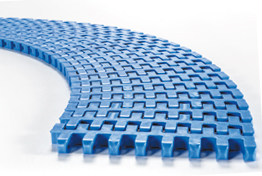

- Conveying in Curved or Inclined Configurations:

Modular belts are highly flexible and can easily navigate curved or inclined conveyor configurations. The individual modules of the belt can flex and adapt to different curves or angles, resulting in smooth and efficient material flow. This capability is particularly beneficial in industries where space constraints or complex layouts require curved or inclined conveyors. Examples include the food and beverage industry, where modular belts enable the transportation of products around corners or between different elevations.

- Easy Maintenance and Replacement:

Modular belts offer advantages in terms of maintenance and replacement compared to other types of conveyor belts. The modular design allows for easy access and removal of individual modules, simplifying cleaning and maintenance tasks. If a section of the belt is damaged or worn out, only the affected modules need to be replaced rather than the entire belt. This modularity reduces downtime and maintenance costs. Industries that prioritize efficient maintenance and quick replacement, such as packaging and logistics, benefit from the ease of maintenance provided by modular belts.

- Hygiene and Cleanliness:

Modular belts are designed with hygiene and cleanliness in mind, making them ideal for industries with strict sanitation requirements. The smooth and non-porous surface of modular belts is easy to clean and resistant to contaminants. They can withstand regular washdown procedures and maintain high levels of hygiene. Industries such as food processing, pharmaceuticals, and healthcare benefit from the hygienic properties of modular belts, as they help prevent cross-contamination and ensure compliance with industry regulations.

- Customization and Adaptability:

Modular belts offer a high level of customization and adaptability to meet specific material handling needs. The modular design allows for easy configuration changes, such as adjusting the width or length of the belt, adding or removing modules, or incorporating specialized features. This flexibility makes modular belts suitable for industries with diverse product sizes, shapes, and handling requirements. Customizable modular belts are commonly used in industries such as automotive manufacturing, where different components with varying sizes and weights need to be transported on the same conveyor system.

While modular belts excel in these specific applications, it’s important to note that conveyor belt selection should consider various factors, including the specific industry, product characteristics, operating conditions, and budget. Different types of conveyor belts may be more suitable for certain applications, and consulting with experts in the field can help determine the best choice for each material handling scenario.

editor by CX 2024-04-19